Content:

1

Product number:

9739242

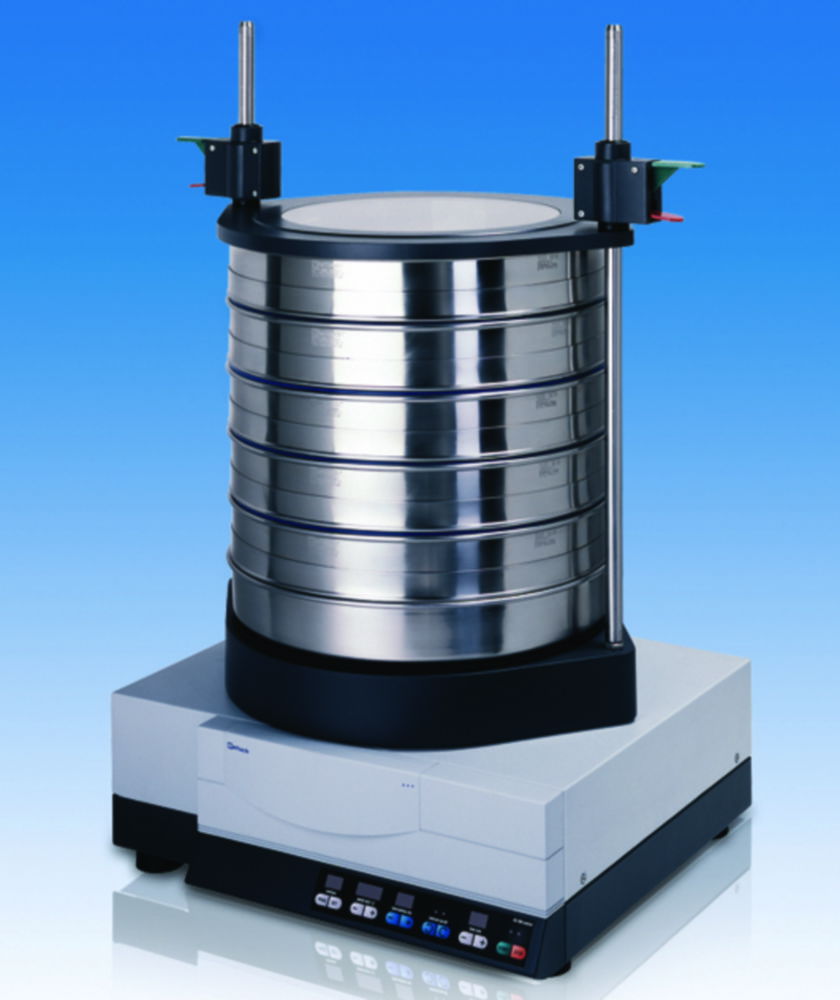

Product information "Analytical sieve shakers AS 400 control"

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.

The AS 400 control is used for the sieving of dry goods with test sieves of a diameter up to 400 mm. The uniform, horizontal circular motion ensures exact separation of the product to be sieved.

Please order clamping device, test sieves and collecting pan separately.

- Digital adjustment of all process parameters (time, speed, interval)

- Short sieving times

- Sieving with circular sieving motion according to DIN 53477

- Maintenance-free

- Interval operation, 1 ... 10 min

- Max. number of fractions 7/9/17

- Memory for up to 9 SOPs

- Integrated interface for evaluation software EasySieve®

Please order clamping device, test sieves and collecting pan separately.

| Depth: | 507 mm |

|---|---|

| Dimensions (WxDxH): | 540 x 507 x 260 mm |

| Height: | 260 mm |

| IP code: | IP 21 |

| Manufacturer Article Number: | 30.022.0001 |

| Max. feed quantity: | 5000 g |

| Max. measurement: | 63 mm |

| Max. sieve stack height: | 510 mm |

| Max. sieve stack mass: | 15 kg |

| Max. voltage: | 240 V |

| Measurement range: | 0.045 ... 63 mm |

| Min. measurement: | 0.045 mm |

| Min. voltage: | 100 V |

| Plug type: | EU |

| Power supply: | 100 ... 240 V, 50/60 Hz |

| Power supply frequency: | 50/60 Hz |

| Type of sieving: | Dry sieving |

| Usable sieve diameters: | 100/200/203/305/315/400 mm |

| Weight: | 70 kg |

| Width: | 540 mm |